Yangzhou Xinyang Technology Co., Ltd. has been focusing on the production of glass fiber reinforced plastic pipes for many years, and has been widely used in oil fields and chemical industries at home and abroad. The specific product information is as follows:

main advantage:

1. Has good corrosion resistance, high temperature resistance and high pressure resistance

2. The inner wall is smooth, no scaling, no wax, not easy to block

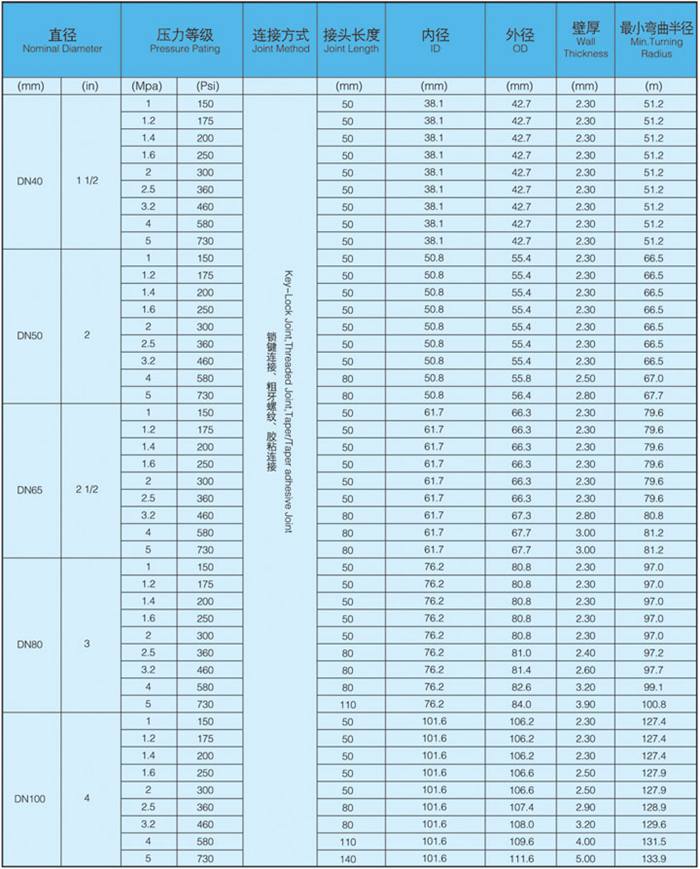

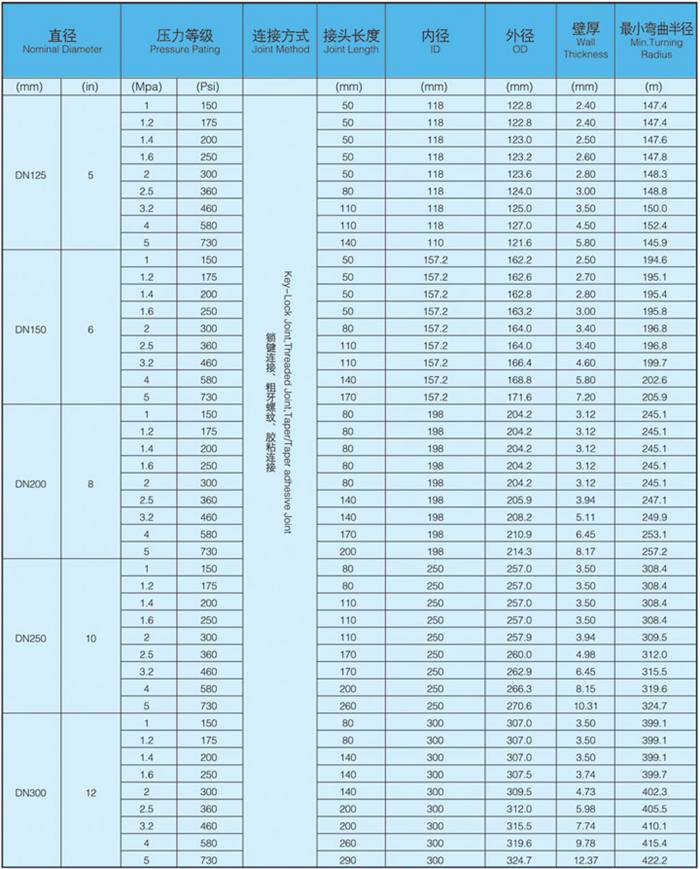

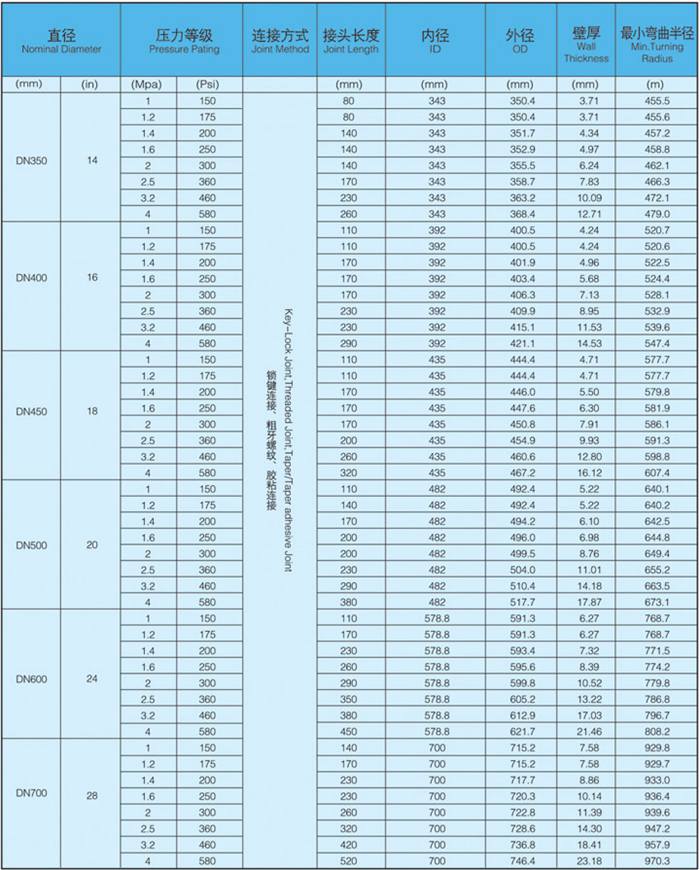

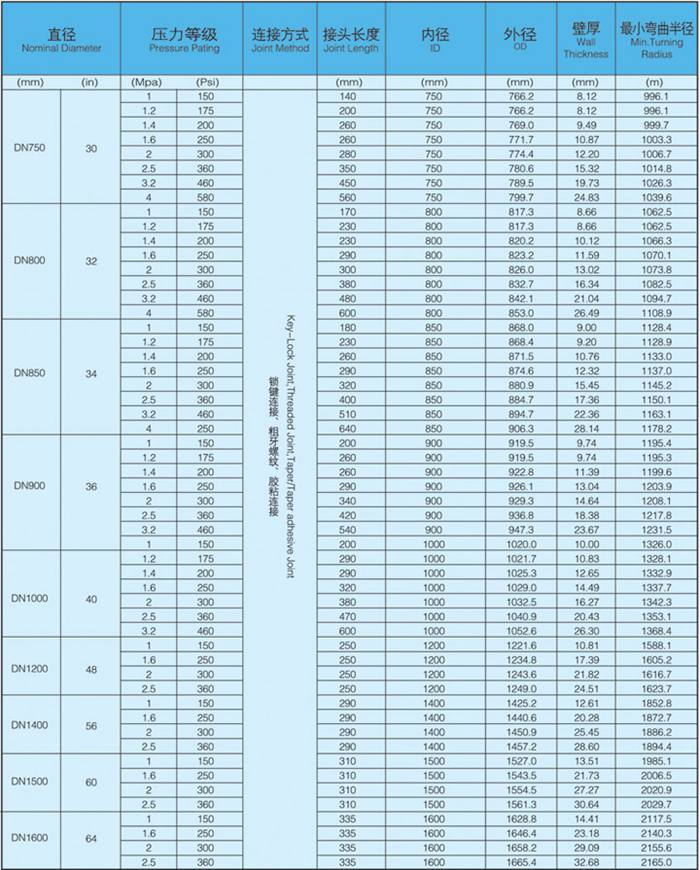

3. The pipe diameter is 1.5 inches-64 inches

4. Working temperature up to 80℃

5. The pressure level is 0.5Mpa to 5Mpa

6. Lightweight and high strength, easy to transport and install

7. Long service life, the design life is not less than 30 years

main application:

1. Brine, brine, water, crude oil, natural gas pipelines

2. Oilfield sewage, chemical sewage and wastewater treatment pipelines

3. Polymer solution delivery line

4. Marine piping

|

Property of Corrosion-resistant

|

|

Chemical

|

Percentage( %)

|

Temp

|

|

℉

|

℃

|

|

Acid

|

|

Mud acid (containing Hydrogen fluoride)

|

|

Not recommended

|

Not recommended

|

|

Hydrochloric acid

|

1-3%

|

75

|

25

|

|

Hydrochloric acid

|

>4%

|

Not recommended

|

Not recommended

|

|

Sulfuric acid

|

1-3%

|

75

|

25

|

|

Sulfuric acid

|

4-10%

|

Not recommended

|

Not recommended

|

|

Alkali

|

|

Sodium hydroxide

|

5-50%

|

Not recommended

|

Not recommended

|

|

Ammonia

|

28%

|

Not recommended

|

Not recommended

|

|

Alcohol乙醇

|

|

Ethylene Glycol

|

Any

|

150

|

65

|

|

Isopropyl alcohol

|

10%

|

100

|

38

|

|

Mercaptoethanol

|

100%

|

75

|

25

|

|

Methyl alcohol

|

20%

|

100

|

38

|

|

Hydrocarbon

|

|

Crude oil containing CO2 or H2S

|

Any

|

150

|

65

|

|

Various gasolene

|

Any

|

150

|

65

|

|

Aircraft fuel

|

Any

|

150

|

65

|

|

Crude oil

|

Any

|

100

|

38

|

|

Kerosene

|

Any

|

150

|

65

|

|

Diesel Oil

|

Any

|

150

|

65

|

|

Water水

|

|

Hypochlorous acid solution

|

100 ppm

|

100

|

38

|

|

Bromide water/ Brine water/KCl solution/Hard water

|

Any

|

150

|

65

|

|

Solution containing CO2 or H2S

|

Any

|

150

|

65

|

|

Soft water/Distilled water

|

Any

|

100

|

38

|

|

Sea water

|

Any

|

150

|

65

|

|

Solvent溶剂

|

|

Benzene

|

<10%

|

75

|

25

|

|

Heptane

|

Any

|

125

|

50

|

|

Ethane

|

Any

|

75

|

25

|

|

Methyl chloride

|

Any

|

Not recommended

|

Not recommended

|

|

Toluene 甲苯

|

Any

|

100

|

38

|

|

Dimethylbenzene

|

..

|

Not recommended

|

Not recommended

|

|

Gas气体

|

|

Dry/humid atmosphere

|

Any

|

150

|

65

|

|

Dry hydrogen sulfide

|

Any

|

150

|

65

|

|

Humid hydrogen sulfide (Weight %) <500 psi<500 psi

|

<5% H2S

|

125

|

50

|

|

Humid hydrogen sulfide (Weight %) >500 psi>500 psi

|

>5% H2S

|

Not recommended

|

Not recommended

|

|

Methane, natural gas

|

Any

|

150

|

65

|

|

Dry ice, <800 psi,<800 psi

|

Any

|

150

|

65

|

|

Dry ice, >800 psi,>800 psi

|

..

|

Not recommended

|

Not recommended

|

|

Wet carbon dioxide, <800 psi <800 psi

|

Any

|

150

|

65

|

|

Wet carbon dioxide, >800 psi>800 psi

|

..

|

Not recommended

|

Not recommended

|

|

Physical Property

|

|

Pipe property

|

Unit

|

Value

|

ASTM method

|

|

Heat conduction coefficient

|

Btu.in/(hr.ft.℉)

|

0.19

|

ASTM D177

|

|

w/m.℃

|

0.33

|

HVTM

|

|

Heat expansion coefficient

|

10ˉ6in/in/℉

|

12.30

|

ASTM D696

|

|

10ˉ6mm/mm/℃

|

22.40

|

ASTM D696

|

|

Flow coefficient

|

Hazen Williams

|

150.00

|

HVTM

|

|

Absolute roughness

|

10ˉ6 ft

|

17.40

|

HVTM

|

|

10ˉ6 m

|

5.30

|

HVTM

|

|

Density

|

Ib/in3

|

121.74

|

ASTM D792

|

|

g/cm3

|

1.95

|

ASTM D792

|

|

Hoop tensile strengh

|

Mpa

|

340.00

|

ASTM D1599

|

|

Toroidal elastic modulus

|

Gpa

|

24.10

|

ASTM D1599

|

|

Hoop Poisson’s ratio

|

-

|

0.40

|

ASTM D1599

|

|

Longiludinal tensile strength

|

Mpa

|

74.00

|

ASTM D2105

|

|

Axial elastic modulus

|

Gpa

|

10.30

|

ASTM D2105

|

|

Axial Poisson’s ratio

|

-

|

0.38

|

ASTM D2105

|

|

Beam elastic modulus

|

Gpa

|

14.40

|

ASTM D695

|

|

hydrostatic design basis

|

Mpa

|

143.00

|

ASTM D2992

|

|

Acid Anhydride TG

|

℃

|

≥117

|

API

|

|

Safety Coefficient( high pressure)

|

Mpa

|

2 times of working pressure

|

API 15HR

|

|

Safety Coefficient(low pressure)

|

Mpa

|

3 times of working pressure

|

API 15LR

|

|